Get Creative — the Fontana Spray Rings are made of Stainless Steel and feature adjustable nozzles, telescopic legs and a series of innovations. The precise engineering and manufacturing of these systems, allows you to create excellent-formed fountains that will work reliably under the harshest environmental conditions.

Similar to the Spray Lines, Spray Rings are the easiest, most cost-effective and durable way to create rings of water. With standard models ranging from 58 cm in diameter up to 10.7 meters, tube thicknesses of ø35 to ø114 and a multitude of nozzle orifices, there is a solution for every application that requires round-shaped, low-cost and high quality spray effect. If however you don’t find something among the standard models, we can create any size and water effect Spray Rings – like the photo above where a 21-meter spray ring was manufactured.

The lightweight, yet heavy duty spray systems are made of superior quality 304 stainless steel and incorporate brass, nickel plated adjustable nozzles, with an option of the entire system to be made of 316 stainless steel. All water inlets of the Spray Rings are male threaded and every one of them is fitted with a flow diverter to achieve optimum performance. All jets (>5mm) have integral flow straighteners for excellent water flow and greater efficiency. Larger models are dispatched split in 2-6 segments (with flange connections) for safer and easier transportation. In addition, all Spray Rings are shipped equipped with placeholders for detachable, adjustable telescopic legs and luminaire mounting brackets making installation quicker than ever before.

Standard models have perpendicular arranged (15° adjustable) nozzles, but all Spray Rings can be tailor-made with 35° inwards or outwards nozzle arrangement. Add to this the extra 15° swivel adjustability of the smooth bore nozzles and you can have an outwards or inwards water dome of up to 50°. In such applications please note that the accessory “Nozzle Extension” is required.

All these contribute to the most complete Spray Rings solution available in the market.

- The Best Solution for Water Rings

- From Fine-Spray to Massive Water Effects

- Vertical or Parabolic Water Streams

- Up to 50° Spray Angle (on request)

- Standard models from 58cm up to 10.7 meters diameter

- Stainless Steel AISI 304

Entirely in 316 on request - Lightweight, yet heavy duty construction

- Multitude of dimensions, tube thicknesses and nozzle orifices

- Ship standard with placeholders for telescopic legs and luminaires

- Flow diverters on every inlet

- Minimum flow capacity required

Application Inspiration:

The most well-designed Spray Rings.

Perfectly Spaced Lighting

Each Spray Ring comes with placeholders for lights at the right spots to achieve optimum lighting distribution.

Telescopic Feet

Pre-assigned locations for adjustable mounting feet to aid perfect alignment and even weight distribution.

Precise Nozzle Arrangement

Nozzles are laser-guided laid out across the circumference of the ring with exceptional precision.

Heavy Duty Stainless Steel

All Fontana Spray Rings are made to last. The heavy-duty Stainless Steel construction ensures the longevity of your fountain.

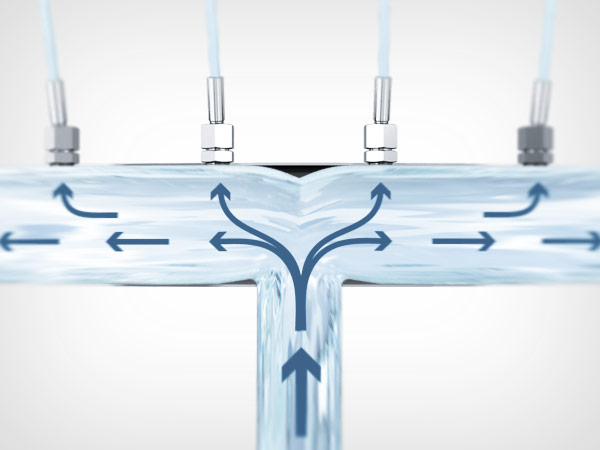

Evenly Spaced “Smart” Inlets

The water inlets of the Spray Rings are evenly spaced and feature an internal flow diverter for optimum hydraulic performance and uniform water effect.

A Flow Straightener Inside Every Nozzle

This great little accessory eliminates pump’s turbulence and straightens the incoming water. The stream then comes out taller, smoother and crystal-clear.

A Flow Diverter on Every Inlet

There are flow diverters on every inlet which in combination with the nozzles’ flow straighteners, achieve optimum performance and water efficiency.

15° Adjustable

All Smooth Bore nozzles are adjustable by 15° in any direction, providing enhanced design flexibility, so that you can create precise water patterns of various shapes.

Accessories & Options

Luminaire Mounting Bracket

Don’t forget that the illumination of a fountain is what makes it a truly unique spectacle at night. This Mounting Bracket fits on the placeholders of Spray Rings, it’s made of Stainless Steel and it is designed to hold all types of luminaires pointing straight up or at any spray angle. It can be mounted in the inside or the outside of any Spray Ring.

For luminaires UL600 – UL700: RSA 2010For luminaires UL800 – UL1000: RSA 2030

Up to 35° Mounted Nozzles – Inwards or Outwards

All Spray Rings can be tailor-made with 35° inwards or outwards nozzle arrangement for water domes of up to 50° (in combination with nozzles’ 15° swiveling). If selected as an option, accessory “Nozzle Extension” is required.

At the end of Spray Ring’s model add suffix:.IPXX – For Inwards mounted nozzles and replace “XX” with angle

.OPXX – For Outwards mounted nozzle and replace “XX” with angle

Telescopic Legs

Essential accessory for mounting spray rings at the desired height. These legs are fastened directly on spray rings’ placeholders and they are adjustable in height by 20cm for water depth between 35-55cm. Can be custom-made on request.

RSA 2020Nozzle Extension

You can order your Spray Ring with nozzle extensions as an option. These extensions allow greater spray angles while placing the tube deeper into water. Nozzle extensions are made of stainless steel. Standard length 80mm (customizable).

Add suffix: .NECustom Spray Rings

We know that every fountain is unique and every new creation exceeds old demands. Every product, every service and essentially every aspect of Fontana is focused on this principle: Breathing life into inspiration. You can always contact us for any kind of special construction — of any scale — and you can expect the same high level of quality that comes along with our standard products.

Even though we provide a wide range of standard products, we supply Build-to-Order equipment based on standard models or entirely different to fulfill each project’s unique requirements. If you have some special design or you are seeking for professional assistance, don’t hesitate to contact us.

Spray Rings have literally no limits in customization. Either it is the diameter of the ring or the spray effect (as delicate as 3.0mm of clear water or as massive as 300mm frothy Fizz jets or any other specialty jets), multi-color illumination or spraying angle, we can design, manufacture and supply you with superior equipment, strictly meeting the project’s requirements and our renowned high quality standards.

Technical Specifications

RS 3XX Series

Tube: ø35 mm | Nozzle Orifice: 3 mm

| Model | Ring Diameter |

No. of Nozzles | Nozzle Orifice |

No. of Inlets | Inlet(s) |

Placeholders for Telescopic Legs |

Placeholders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 |

| Head [m] | 0.7 | 1.3 | 2.1 | 2.8 | |||||||||

| RS 305 | 0.58 | 14 | 3.0 | 1 | ¾” | 3 | 3 | 1 | L/min | 22 | 29 | 37 | 43 |

| RS 307 | 0.76 | 18 | 3.0 | 1 | ¾” | 3 | 3 | 1 | L/min | 28 | 38 | 48 | 55 |

| RS 309 | 0.90 | 20 | 3.0 | 1 | ¾” | 3 | 4 | 1 | L/min | 31 | 42 | 53 | 62 |

| RS 312 | 1.15 | 24 | 3.0 | 1 | ¾” | 3 | 4 | 1 | L/min | 37 | 50 | 63 | 74 |

| RS 315 | 1.50 | 32 | 3.0 | 1 | ¾” | 3 | 4 | 1 | L/min | 49 | 67 | 84 | 99 |

| RS 318 | 1.81 | 38 | 3.0 | 2 | ¾” | 4 | 6 | 1 | L/min | 59 | 79 | 100 | 117 |

| RS 321 | 2.12 | 44 | 3.0 | 2 | ¾” | 4 | 6 | 2 | L/min | 68 | 92 | 116 | 136 |

RS 5XX Series

Tube: ø50 mm | Nozzle Orifice: 4 mm

Model |

Ring Diameter |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

| Head [m] | 0.7 | 1.3 | 2.0 | 2.8 | 3.4 | 4.2 | |||||||||

| RS 505 | 0.58 | 14 | 4.0 | 2 | 1” | 3 | 3 | 1 | L/min | 35 | 51 | 62 | 71 | 80 | 89 |

| RS 507 | 0.76 | 18 | 4.0 | 2 | 1” | 3 | 3 | 1 | L/min | 46 | 65 | 79 | 91 | 103 | 115 |

| RS 509 | 0.90 | 20 | 4.0 | 2 | 1” | 3 | 4 | 1 | L/min | 51 | 73 | 88 | 101 | 114 | 128 |

| RS 511 | 1.15 | 24 | 4.0 | 2 | 1” | 3 | 4 | 1 | L/min | 61 | 87 | 106 | 121 | 137 | 153 |

| RS 515 | 1.50 | 32 | 4.0 | 2 | 1” | 3 | 4 | 1 | L/min | 81 | 116 | 141 | 162 | 183 | 204 |

| RS 518 | 1.81 | 38 | 4.0 | 2 | 1” | 4 | 6 | 1 | L/min | 96 | 138 | 167 | 192 | 217 | 242 |

| RS 521 | 2.12 | 44 | 4.0 | 2 | 1” | 4 | 6 | 2 | L/min | 111 | 160 | 194 | 223 | 252 | 281 |

| RS 528 | 2.80 | 58 | 4.0 | 2 | 1” | 4 | 8 | 2 | L/min | 147 | 211 | 255 | 293 | 332 | 370 |

| RS 535 | 3.50 | 72 | 4.0 | 3 | 1” | 6 | 12 | 3 | L/min | 182 | 261 | 317 | 364 | 412 | 459 |

RS 6XX Series

Tube: ø51, ø60, ø63, ø76 mm | Nozzle Orifice: 5 mm

Model |

Ring Diameter |

Tube ø |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 |

| Head [m] | 0.8 | 1.4 | 2.0 | 2.9 | 3.1 | 3.9 | 4.5 | ||||||||||

| RS 605 | 0.52 | 51 | 10 | 5.0 | 2 | 1” | 3 | 3 | 1 | L/min | 41 | 64 | 72 | 83 | 91 | 102 | 110 |

| RS 609 | 0.91 | 60 | 14 | 5.0 | 2 | 1¼” | 3 | 4 | 1 | L/min | 57 | 89 | 100 | 116 | 128 | 142 | 154 |

| RS 615 | 1.51 | 60 | 24 | 5.0 | 2 | 1¼” | 3 | 4 | 1 | L/min | 98 | 153 | 172 | 198 | 219 | 244 | 264 |

| RS 618 | 1.80 | 60 | 28 | 5.0 | 2 | 1¼” | 4 | 6 | 1 | L/min | 114 | 179 | 200 | 231 | 256 | 285 | 308 |

| RS 621 | 2.16 | 63 | 34 | 5.0 | 2 | 1½” | 4 | 6 | 1 | L/min | 138 | 217 | 243 | 281 | 310 | 346 | 374 |

| RS 628 | 2.85 | 63 | 44 | 5.0 | 2 | 1½” | 4 | 8 | 2 | L/min | 179 | 281 | 315 | 363 | 402 | 447 | 483 |

| RS 635 | 3.56 | 63 | 56 | 5.0 | 4 | 1½” | 6 | 12 | 2 | L/min | 228 | 357 | 400 | 462 | 511 | 569 | 615 |

| RS 644 | 4.40 | 63 | 68 | 5.0 | 4 | 1½” | 6 | 12 | 4 | L/min | 277 | 434 | 486 | 561 | 621 | 691 | 747 |

| RS 653 | 5.35 | 63 | 84 | 5.0 | 4 | 1½” | 8 | 16 | 4 | L/min | 342 | 536 | 601 | 693 | 767 | 854 | 923 |

| RS 661 | 6.06 | 63 | 96 | 5.0 | 4 | 1½” | 9 | 18 | 4 | L/min | 391 | 612 | 686 | 792 | 876 | 976 | 1055 |

| RS 668 | 6.88 | 76 | 108 | 5.0 | 4 | 2” | 9 | 18 | 4 | L/min | 440 | 689 | 772 | 891 | 986 | 1098 | 1187 |

| RS 681 | 8.15 | 76 | 128 | 5.0 | 4 | 2” | 10 | 20 | 5 | L/min | 521 | 817 | 915 | 1056 | 1169 | 1301 | 1406 |

RS 7XX Series

Tube: ø51, ø60, ø63, ø76 mm | Nozzle Orifice: 6 mm

Model |

Ring Diameter |

Tube ø |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 |

| Head [m] | 0.7 | 1.3 | 2.0 | 2.6 | 3.2 | 4.0 | 4.6 | 5.4 | ||||||||||

| RS 705 | 0.52 | 51 | 10 | 6.0 | 2 | 1” | 3 | 3 | 1 | L/min | 59 | 82 | 102 | 119 | 134 | 148 | 162 | 175 |

| RS 709 | 0.91 | 60 | 14 | 6.0 | 2 | 1¼” | 3 | 4 | 1 | L/min | 82 | 120 | 149 | 176 | 200 | 219 | 239 | 259 |

| RS 715 | 1.51 | 60 | 24 | 6.0 | 2 | 1¼” | 3 | 4 | 1 | L/min | 140 | 206 | 256 | 301 | 343 | 375 | 409 | 444 |

| RS 718 | 1.80 | 60 | 28 | 6.0 | 2 | 1¼” | 4 | 6 | 1 | L/min | 163 | 240 | 299 | 351 | 400 | 437 | 477 | 517 |

| RS 721 | 2.16 | 63 | 34 | 6.0 | 2 | 1½” | 4 | 6 | 1 | L/min | 201 | 280 | 348 | 406 | 455 | 504 | 552 | 596 |

| RS 728 | 2.85 | 63 | 44 | 6.0 | 2 | 1½” | 4 | 8 | 2 | L/min | 257 | 378 | 469 | 552 | 629 | 687 | 750 | 813 |

| RS 735 | 3.56 | 63 | 56 | 6.0 | 4 | 1½” | 6 | 12 | 2 | L/min | 331 | 461 | 573 | 669 | 750 | 830 | 909 | 981 |

| RS 744 | 4.40 | 63 | 68 | 6.0 | 4 | 1½” | 6 | 12 | 4 | L/min | 402 | 560 | 696 | 812 | 910 | 1008 | 1104 | 1192 |

| RS 753 | 5.35 | 63 | 84 | 6.0 | 4 | 1½” | 8 | 16 | 4 | L/min | 497 | 692 | 859 | 1003 | 1125 | 1246 | 1364 | 1472 |

| RS 761 | 6.06 | 63 | 96 | 6.0 | 4 | 1½” | 9 | 18 | 4 | L/min | 568 | 791 | 982 | 1147 | 1285 | 1423 | 1559 | 1682 |

| RS 768 | 6.88 | 76 | 108 | 6.0 | 4 | 2” | 9 | 18 | 4 | L/min | 639 | 890 | 1105 | 1290 | 1446 | 1601 | 1753 | 1892 |

| RS 781 | 8.15 | 76 | 128 | 6.0 | 4 | 2” | 10 | 20 | 5 | L/min | 758 | 1055 | 1309 | 1529 | 1714 | 1898 | 2078 | 2243 |

RS 8XX Series

Tube: ø89 mm | Nozzle Orifice: 8 mm

Model |

Ring Diameter |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 |

| Head [m] | 0.8 | 1.3 | 2.0 | 2.7 | 3.5 | 4.2 | 5.0 | 5.7 | |||||||||

| RS 815 | 1.50 | 24 | 8.0 | 2 | 2” | 3 | 4 | 1 | L/min | 246 | 348 | 433 | 507 | 574 | 629 | 683 | 731 |

| RS 818 | 1.80 | 28 | 8.0 | 2 | 2” | 4 | 6 | 1 | L/min | 286 | 407 | 505 | 592 | 669 | 734 | 796 | 853 |

| RS 821 | 2.15 | 34 | 8.0 | 4 | 2” | 4 | 6 | 1 | L/min | 348 | 494 | 613 | 718 | 813 | 891 | 967 | 1036 |

| RS 830 | 2.83 | 44 | 8.0 | 4 | 2” | 4 | 8 | 2 | L/min | 450 | 639 | 794 | 930 | 1052 | 1153 | 1252 | 1341 |

| RS 835 | 3.56 | 56 | 8.0 | 4 | 2” | 6 | 12 | 2 | L/min | 573 | 813 | 1010 | 1183 | 1339 | 1468 | 1593 | 1706 |

| RS 845 | 4.40 | 68 | 8.0 | 4 | 2” | 6 | 12 | 3 | L/min | 696 | 987 | 1227 | 1437 | 1625 | 1782 | 1934 | 2072 |

| RS 853 | 5.35 | 72 | 8.0 | 6 | 2” | 8 | 16 | 3 | L/min | 737 | 1045 | 1299 | 1521 | 1721 | 1887 | 2048 | 2194 |

| RS 868 | 6.88 | 84 | 8.0 | 6 | 2” | 9 | 18 | 4 | L/min | 859 | 1220 | 1515 | 1775 | 2008 | 2202 | 2389 | 2559 |

RS 9XX Series

Tube: ø89 mm | Nozzle Orifice: 10 mm

Model |

Ring Diameter |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 |

| Head [m] | 0.9 | 1.5 | 2.3 | 3.2 | 3.9 | 4.7 | 5.5 | 6.3 | 7.1 | |||||||||

| RS 915 | 1.50 | 24 | 10.0 | 2 | 2” | 3 | 4 | 1 | L/min | 409 | 576 | 721 | 826 | 921 | 1003 | 1096 | 1236 | 1278 |

| RS 918 | 1.80 | 28 | 10.0 | 2 | 2” | 4 | 6 | 1 | L/min | 477 | 671 | 841 | 964 | 1075 | 1170 | 1278 | 1441 | 1491 |

| RS 921 | 2.15 | 34 | 10.0 | 4 | 2” | 4 | 6 | 1 | L/min | 580 | 815 | 1021 | 1171 | 1305 | 1421 | 1552 | 1750 | 1810 |

| RS 930 | 2.83 | 44 | 10.0 | 4 | 2” | 4 | 8 | 2 | L/min | 750 | 1055 | 1321 | 1515 | 1689 | 1839 | 2009 | 2265 | 2343 |

| RS 935 | 3.56 | 56 | 10.0 | 4 | 2” | 6 | 12 | 2 | L/min | 955 | 1343 | 1682 | 1928 | 2150 | 2341 | 2556 | 2883 | 2981 |

| RS 945 | 4.40 | 68 | 10.0 | 4 | 2” | 6 | 12 | 3 | L/min | 1159 | 1631 | 2042 | 2341 | 2611 | 2842 | 3104 | 3501 | 3620 |

| RS 953 | 5.35 | 72 | 10.0 | 6 | 2” | 8 | 16 | 3 | L/min | 1228 | 1727 | 2162 | 2479 | 2764 | 3010 | 3287 | 3707 | 3833 |

| RS 968 | 6.88 | 84 | 10.0 | 6 | 2” | 9 | 18 | 4 | L/min | 1432 | 2014 | 2523 | 2892 | 3225 | 3511 | 3835 | 4324 | 4472 |

RS 10XX Series

Tube: ø114 mm | Nozzle Orifice: 12 mm

Model |

Ring Diameter |

No. of Nozzles |

Nozzle Orifice |

No. of Inlets |

Inlet(s) |

Place- holders for Telescopic Legs |

Place- holders for Lights |

Segments* |

Spray Height [m] | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 | 6.0 |

| Head [m] | 0.6 | 1.2 | 1.9 | 2.6 | 3.2 | 3.8 | 5.2 | 6.5 | 8.1 | |||||||||

| RS 1018 | 1.80 | 16 | 12.0 | 2 | 4” | 4 | 6 | 1 | L/min | 366 | 532 | 664 | 759 | 840 | 920 | 1070 | 1200 | 1505 |

| RS 1021 | 2.15 | 20 | 12.0 | 2 | 4” | 4 | 6 | 1 | L/min | 458 | 665 | 831 | 948 | 1049 | 1151 | 1338 | 1500 | 1882 |

| RS 1030 | 3.00 | 26 | 12.0 | 2 | 4” | 6 | 8 | 2 | L/min | 595 | 864 | 1080 | 1233 | 1364 | 1496 | 1739 | 1951 | 2446 |

| RS 1035 | 3.56 | 28 | 12.0 | 2 | 4” | 6 | 12 | 2 | L/min | 641 | 931 | 1163 | 1327 | 1469 | 1611 | 1873 | 2101 | 2634 |

| RS 1045 | 4.45 | 36 | 12.0 | 3 | 4” | 6 | 12 | 3 | L/min | 824 | 1197 | 1495 | 1707 | 1889 | 2071 | 2408 | 2701 | 3387 |

| RS 1068 | 6.88 | 60 | 12.0 | 4 | 4” | 9 | 18 | 4 | L/min | 1373 | 1995 | 2492 | 2845 | 3148 | 3452 | 4013 | 4501 | 5645 |

| RS 1089 | 8.90 | 72 | 12.0 | 6 | 4” | 12 | 24 | 5 | L/min | 1648 | 2394 | 2990 | 3414 | 3778 | 4142 | 4816 | 5401 | 6774 |

| RS 1090 | 10.7 | 84 | 12.0 | 6 | 4” | 14 | 28 | 6 | L/min | 1923 | 2793 | 3488 | 3982 | 4407 | 4833 | 5619 | 6302 | 7903 |

*Amount of segments (with flange connections) the spray ring is split into for easier transportation and installation.

For 316 Stainless Steel add suffix .316

Downloads

You can download any of the following files for your own personal use. Information contained in these files might change without prior notice. Copy in part or in whole, as well as reproduction, publication, distribution or any other use are strictly prohibited without written consent by Fontana.